Engineering Capabilities

The PHPK engineering group is uniquely staffed to supply our customers with tailored designs of piping and systems ranging from a single vacuum jacketed spool to the design and manufacture of highly complex systems for advanced cryogenics processes. Our strategic partnership with Mid-Ohio Products, the largest machining operation in central Ohio, allows our team immediate response to prototype and custom designs. Our professional engineers, designers, and drafters are skilled in the use of the most current tools available to the industry including:

- 3D solid modeling

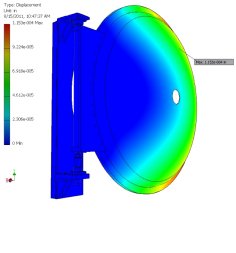

- stress analysis using finite element software

- piping thermal flexibility with seismic and wind analysis

- ASME pressure vessel design analysis software

As a standard, PHPK pipe products and components meet the ASME B31.3 code, and our vacuum and pressure vessels are designed in accordance with the ASME Boiler and Pressure Vessel code with optional code stamp.

Additional capabilities include:

- custom design variations of our standard products to meet the clients specific needs

- custom designed PLC logic and controls

- relief valve sizing to ASME code

- thermal heat leak analysis

- design of pressure vessels to meet lethal service requirements for ASME code stamp

- design of test apparatuses to meet specific verifications

- research and development of custom products and processes

PHPK’s controls division offers full service design, fabrication, programming and start-up services. Their expertise includes control systems for Vacuum Chambers, Temperature Control Units (TCUs), Fill Stations and Vapor Recovery Units to name a few. PHPK offers designs based on any number of PLC brands based on customer requirements. Control system options include remote control, touch screen, remote monitoring, UPS back-up and optional electrical UL stamp on cabinet designs.